Laboratory of Mechanics

Head of the Technological Networks and Laboratories Functional Unit: Gianluca LAZZARO

E-mail: gianluca.lazzaro@ingv.it

Referent of laboratory of mechanics: Paolo COSENZA

E-mail:paolo.cosenza@ingv.it

Employee of Laboratory of mechanics: Filippo ALTAVILLA

E-mail: filippo.altavilla@ingv.it

E-mail: laboratoriodimeccanica.pa@ingv.it

Tel: 3351028746

Laboratory of Mechanics

The laboratory of mechanics carries out activities of technical support to the volcanic and seismic surveillance. It was created in 1995 and deals with the resolution of technical and practical problems occurring during the research and surveillance activities. It gives appropriate solutions to make sampling in extreme environmental conditions, typical of the areas concerned by volcanic fluids emissions. The lab also deals with the design and implementation of portable instruments, suitable for harsh environments, for sampling and gas/water analyses

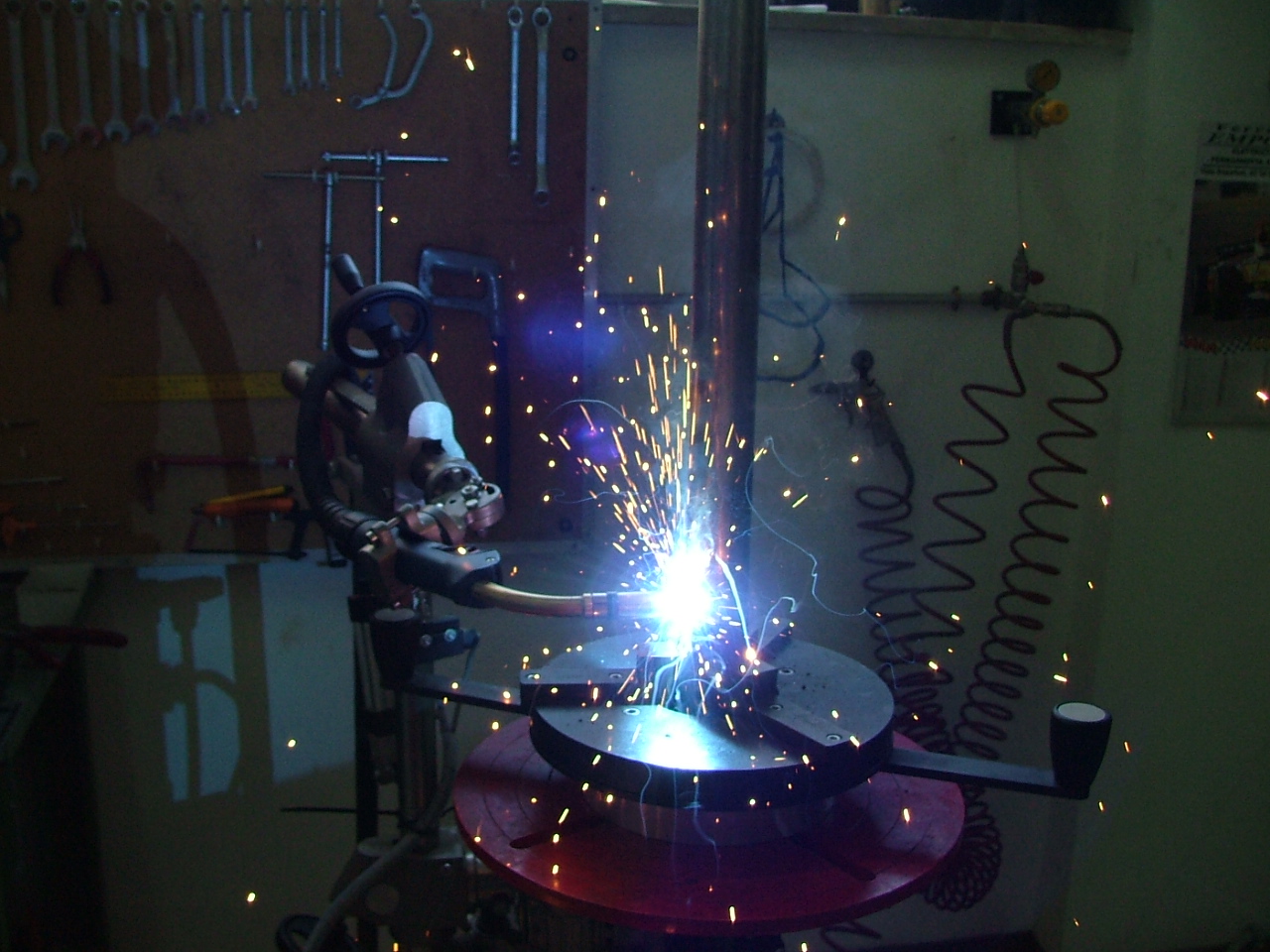

The execution of various types of processing, occurs through an initial planning stage, carried out with the aid of software CAD 2D and Autodesk 3D, which it is possible to design with, define dimensional calculations being clear, right from the start, what the final appearance and the result of every single work will be. This followed by an implementation phase, which begins with an accurate choice of materials that, used in the construction of the prototype, must possess special properties, for example resistance to aggressive agents present in the active volcanic areas. The development and realization processes are documented to trace any problem encountered during construction.

The mechanical components Hardware (containers, frames, structures welded or bolted, boxes etc.) that go to form every single work, are developed in collaboration with other laboratories (electronic, gas and water analysis) to cope with all the problems that occur, quickly getting to a working and easy to use product. On many occasions, exceeded the laboratory tests, the prototypes are tested in real conditions of use.

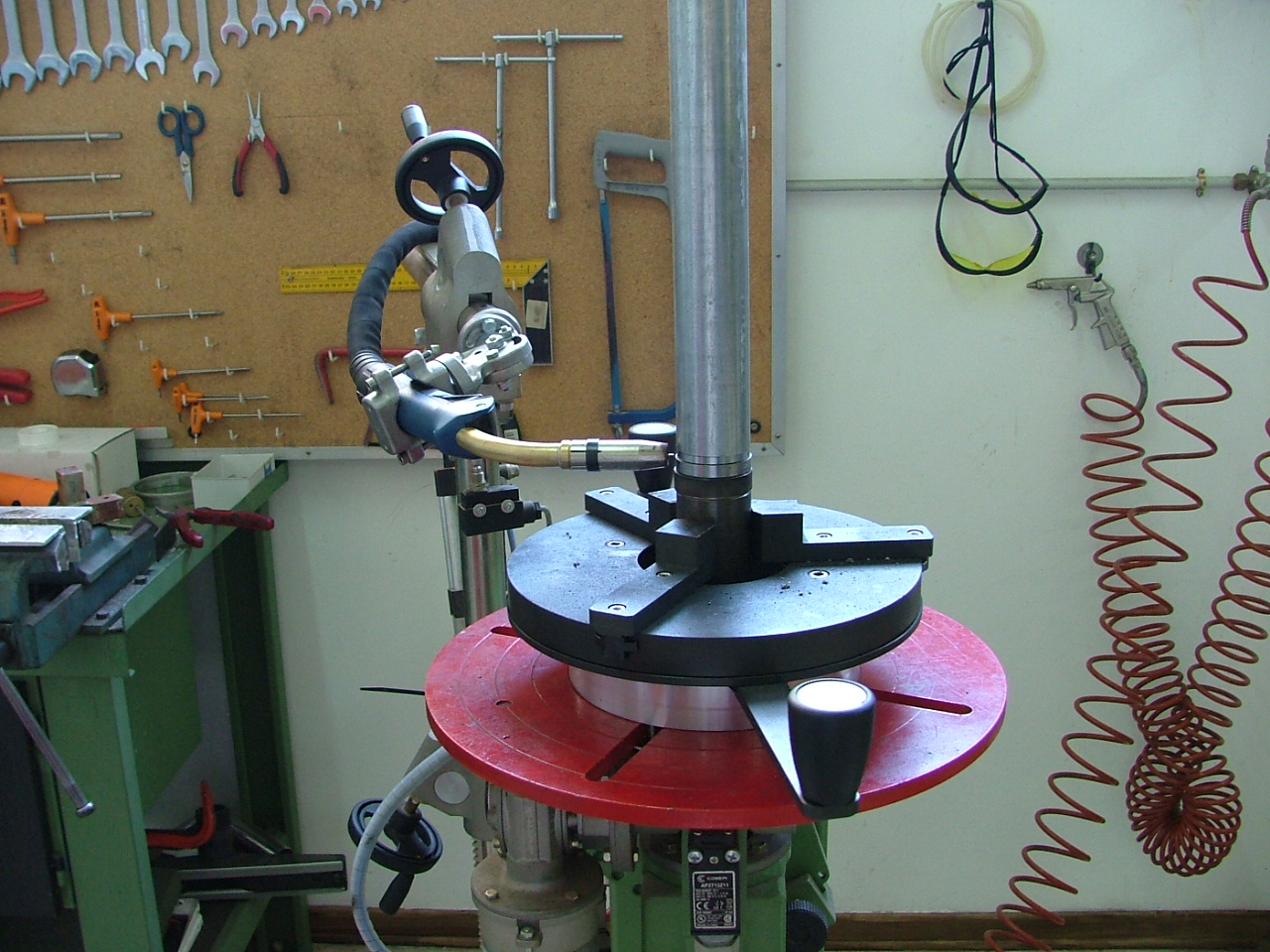

The laboratory has different types of machinery and equipment. Some of these are used for removal of shavings such as: the parallel lathe, the vertical milling machine, the band saw and the radial drill; other machinery and equipment for the metallic carpentry, for deformation and metal calendering such as: hydraulic shears, hydraulic press bending, corner shear variable, curve hydraulic pipes, curved profiles, “rotolatrice” calendering, edgebander, sharpening grinder. As regards the vacuum technology, an emptying bench with turbo pump is present, devoted to the testing phases of the instrumentations realized.

The laboratory is equipped with a range of power tools and compressed air, for the realization of several types of jobs (one manual planing mill, one manual circular saw, one nibbler and one manual grinder) and tools for precision measurements such as digital calipers, micrometers, comparators, surface plates and ground prisms. The lab also deals with the maintenance of an adequate warehouse stock of raw and consumable material.

The mechanical laboratory has participated in numerous experimental projects regarding: measurement of gas flows in fumarolic and underwater environment; temperature gradients in soils; disseminated gas flows from soils; chemical and physical parameters; absolute pressure of the gases dissolved in natural waters.

In the past, small productions were carried out serially: the construction of metal sheet boxes made for the measuring stations; supports for solar panels; bases and poles for weather stations; vacuum samplers for gas and water; casings for temperature probes; different types of probes for sampling volcanic fluids etc.

The experiences gained over the years, allowed to acquire expertise in the knowledge of materials, in the operation of machine tools and in the use of vacuum technology.